SoftBurn – CNC Plate Burner Software

Scanner For Autocad Drawings

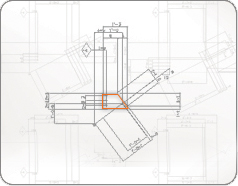

SoftBurn is a CNC Plate Burner Software that Scans virtually any Connection Material sheet or P sheet of plates detailed for fabrication. Soft Burn will scan (read) these drawings of plates, and create full scale DXF or DSTV files for the CNC plate burner. These DXF and DSTV files can then be read in by the CNC plate burning software completely eliminating the need to program the plates manually in the shop.

Input Methods for SoftBurn

Autocad Drawings

Soft Burn will read virtually any DWG or DXF file, typically created by Autocad or other software packages as input. The Connection Material drawing, or P sheet, can consist from one to any number of plates, but should just be connection material, not a full shop drawing of a Column or Beam. The plates on these drawings have to be drawn to some scale (example, 1 inch scale), and each plate can be drawn to a different scale if needed.

Input Methods for SoftBurn

Output Methods for SoftBurn

DXF output Files – The DXF output file generated by SoftBurn will be the full scale drawing of the plate, with all inside corners radiused. The layer used for the plate outline is user defined, typically PLASMA or CUT. The holes will be drawn in layer PUNCH1, PUNCH2, or

PUNCH3, as each of these layers define a hole or tool diameter, and are user defined. These DXF files will be easily read into thesoftware used on your CNC plate burner. DSTV output files, The DSTV output file generated by SoftBurn are the industry standard DSTV file, and

includes all the properties required in the DSTV file including the plate grade, quantity, properties, etc. All inside corners will be radiused, and the plate profile and holes will be accurately reported as well. These DSTV files will be easily read into and software requiring DSTV files.